AI-Powered Corrosion Detection and Prediction for Pipeline Safety

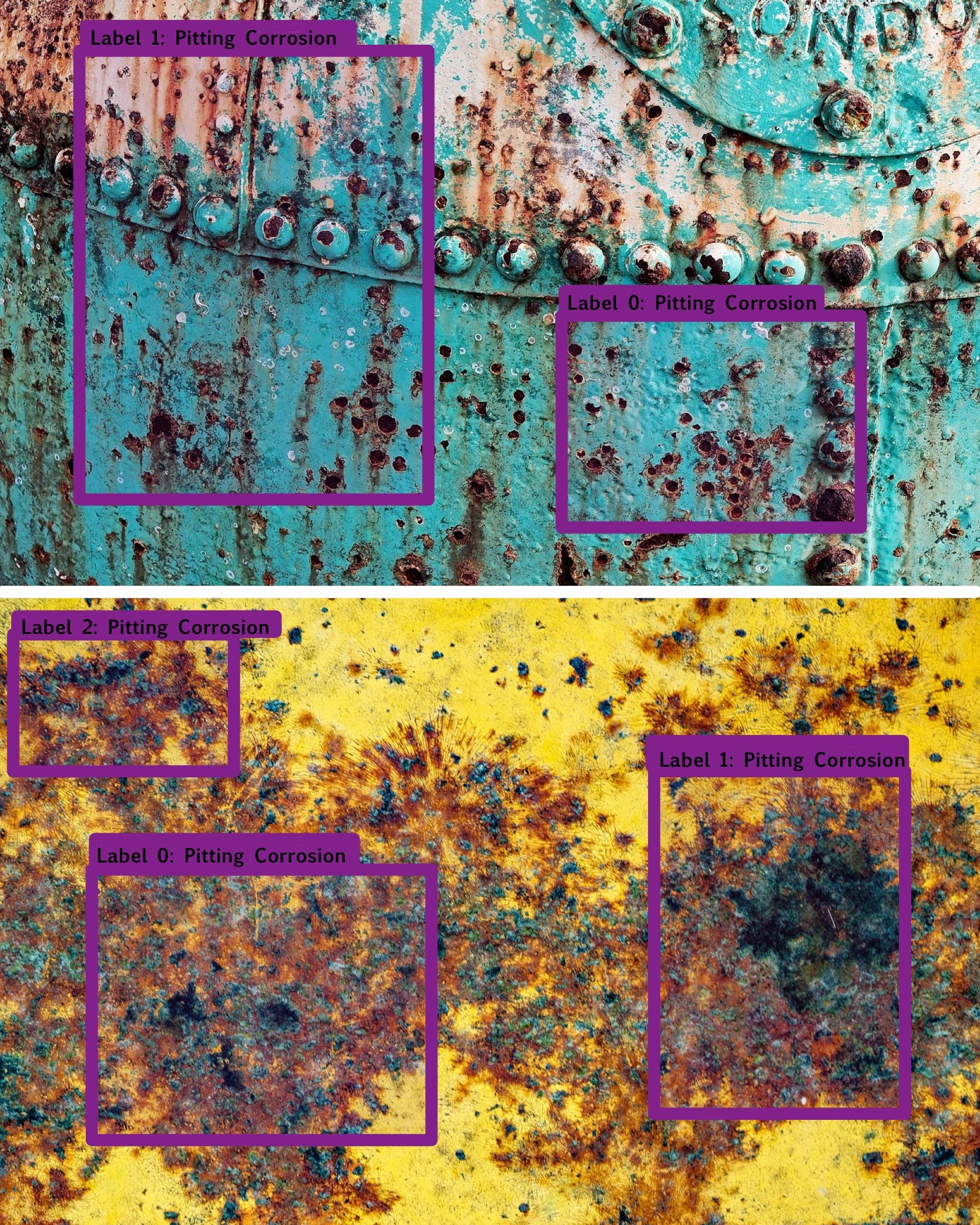

Enhance pipeline integrity with real-time corrosion analysis and predictive modeling. Receive instant alerts and actionable insights for proactive maintenance and risk mitigation.

scenarios